Scientists at Washington State University (WSU) and collaborating institutions have unveiled a promising new method to efficiently convert agricultural residue, specifically corn waste like stalks and husks, into low-cost sugar.

This breakthrough opens a significant new pathway towards developing more sustainable biofuel research and producing valuable bioproducts from renewable sources.

The Promise of Agricultural Biomass

Agricultural residues, collectively known as biomass, represent a vast and underutilized resource. Corn waste, or corn stover – the stalks, leaves, cobs, and husks left in the field after harvest – is particularly abundant.

Utilizing such waste as a feedstock for renewable energy and materials is highly attractive because it doesn’t compete directly with food crops for land use. This makes biomass conversion of agricultural residues a more sustainable alternative compared to using edible parts of plants like corn kernels for ethanol production.

Unlocking the potential within this abundant, inexpensive resource is key to developing renewable energy and biobased chemicals.

The Challenge of Unlocking Biomass’s Potential

Despite its promise, efficiently converting lignocellulosic biomass – tough plant matter rich in cellulose and lignin – into usable sugars has long been a major technical and economic challenge.

Plant cell walls are complex and rigid structures. Lignin, a complex polymer, acts like a glue coating the cellulose fibers, making it difficult for enzymes to access and break down the cellulose (a polymer of glucose) into fermentable sugars like glucose. Overcoming this recalcitrance requires energy-intensive and often costly pretreatment technologies.

A Novel Pretreatment Method Developed

In their newly published research in Bioresource Technology (appearing in the July 2025 issue, published online April 16), the scientists describe the development of a novel experimental process. The core of their method involves a unique pretreatment step for corn stover. They used ammonium sulfite-based alkali salts along with potassium hydroxide at mild temperatures.

This specific combination and method effectively breaks down the complex structure of the biomass, making the cellulose component much more accessible for subsequent steps. The use of mild temperatures is particularly advantageous, potentially reducing energy costs and avoiding the harsh conditions sometimes required in other pretreatment methods.

From Cellulose to Low-Cost Sugar

Following the pretreatment that exposes the cellulose, enzymes are introduced. These specialized enzymes act like biological catalysts, breaking down the cellulosic polymers into simpler sugars, such as glucose. A key finding from the research is the potential to produce this sugar at a remarkably low cost.

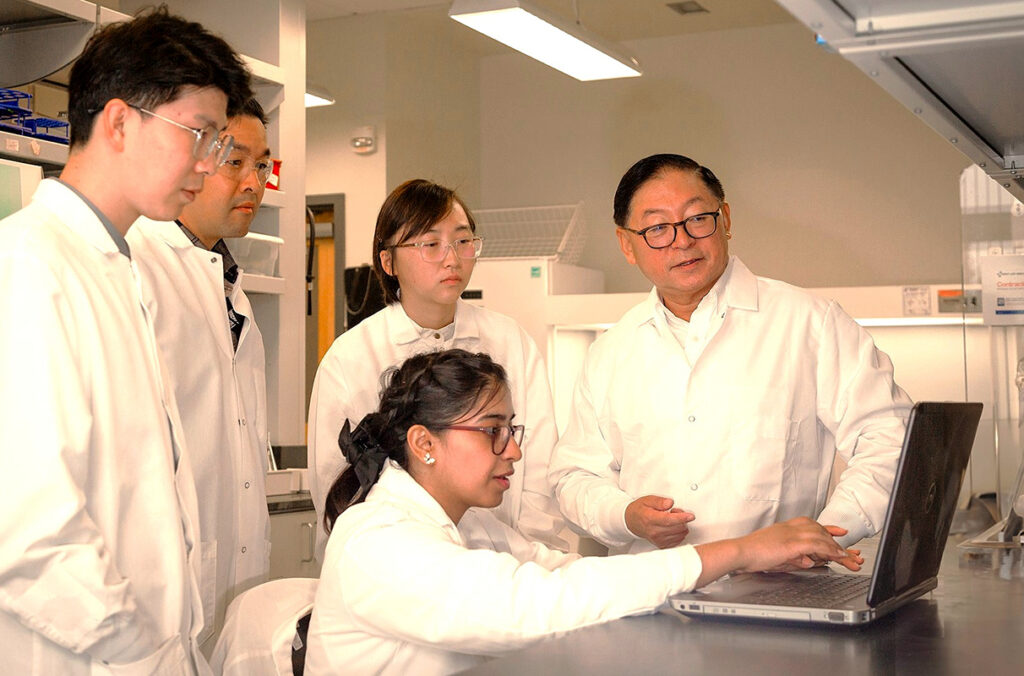

Calculations suggest that the resulting sugar could be sold for as low as 28 cents per pound, making it economically competitive with existing low-cost sugar sources currently used in the biorefinery industry. As Bin Yang, a professor at WSU’s Department of Biological Systems Engineering and a lead investigator on the study, emphasized, “Inexpensive sugar is the key to commercial success for new technologies that make fuels and useful products from renewable biomass.”

A Circular Approach: Utilizing Waste as Fertilizer

Beyond producing affordable sugar, a significant innovation of this process is the utilization of the waste stream. Unlike many industrial processes that generate byproducts requiring disposal, the waste liquor resulting from this pretreatment process does not require chemical recovery and can be repurposed.

The research indicates that this waste liquor can be used as fertilizer, rich in nutrients beneficial to soil. This “no waste stream” approach contributes to a more sustainable and environmentally friendly process, fitting within the concept of a circular bioeconomy where residues from one process become valuable inputs for another.

Using the waste liquor as fertilizer also has the potential to offset production costs, further enhancing the economic feasibility of the entire process. As Yang theorized, this patent-pending process produces high-quality fermentable sugar for the biorefinery as well as a fertilizer that can replenish soil nutrients for farmers.

Economic Feasibility for Biorefineries

The ability to produce low-cost sugar is paramount for the economic success of a biorefinery – the industrial facility that converts plant matter into fuels and valuable products.

Sugar serves as the primary feedstock for fermentation processes that yield biofuels like ethanol or serve as building blocks for various bioproducts such as biodegradable plastics, chemicals, and materials.

By significantly lowering the cost of this key feedstock, the new process makes the entire biomass conversion pathway more competitive with existing production methods that rely on fossil fuels or higher-cost sugar sources. The target price of 28 cents per pound aligns the cost of biomass-derived sugar with prices found in current sugar markets utilized by the bio-based industry.

Collaboration and Funding Support

This extensive research project was a collaborative effort involving multiple institutions. In addition to WSU, contributors included researchers from the University of Connecticut, the National Renewable Energy Laboratory (NREL), the USDA Forest Products Lab in Madison, Wisconsin, and Washington University in St. Louis, Missouri.

The project received funding from the U.S. Department of Energy’s Bioenergy Technologies Office, highlighting its alignment with national goals focused on developing renewable energy sources and biobased products to reduce reliance on fossil fuels and lower greenhouse gas emissions.

Moving Towards Pilot Scale Validation

With the success demonstrated at the laboratory scale, the next critical phase for this technology is advancing to pilot-scale testing. Xiaowen Chen, a scientist at NREL and a principal investigator on the project, stated, “In the next phase, we will be advancing our pretreatment technology at a pilot scale.”

Pilot-scale testing is a crucial step in the commercialization process, allowing researchers and engineers to test the process on a larger scale than the lab, identify potential engineering challenges, optimize operational parameters, and demonstrate the technology’s viability under conditions closer to industrial application before a full-scale biorefinery plant is built.

A Promising Pathway for Sustainable Energy

The discovery of this novel process for converting corn waste into low-cost sugar represents a significant advancement in biofuel research and biomass conversion. Developed through collaborative research, this method utilizes an efficient pretreatment of corn stover under mild conditions and offers a unique circular approach by repurposing the waste liquor as fertilizer, effectively creating a “no waste stream” system.

By demonstrating the potential to produce fermentable sugar at a highly competitive price (as low as 28 cents per pound), this technology holds considerable promise for improving the economic feasibility of biorefineries and unlocking the vast potential of agricultural residues for the production of sustainable energy and valuable bioproducts.

As the technology moves towards pilot-scale validation, it offers a tangible pathway towards a more sustainable and circular bioeconomy.